Catalogs Hide

Here will show you what is Inkjet OLED and Evaporated OLED, and the differences between them.

The inkjet printing OLED process mainly dissolves OLED organic materials into "ink", and then directly prints the "ink" less than tens of pl (one trillionth of a liter) on the surface of the substrate to form R (red), G (green), B (blue) organic light-emitting layers.

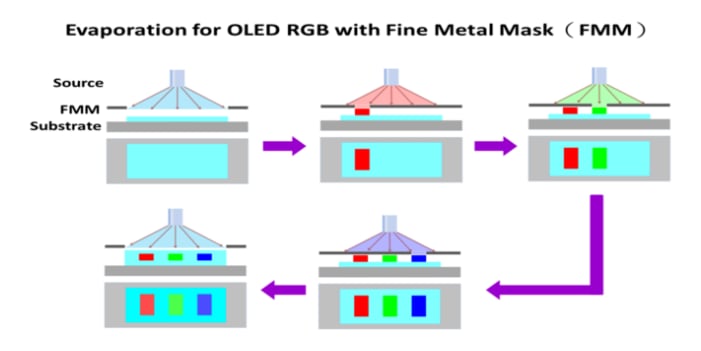

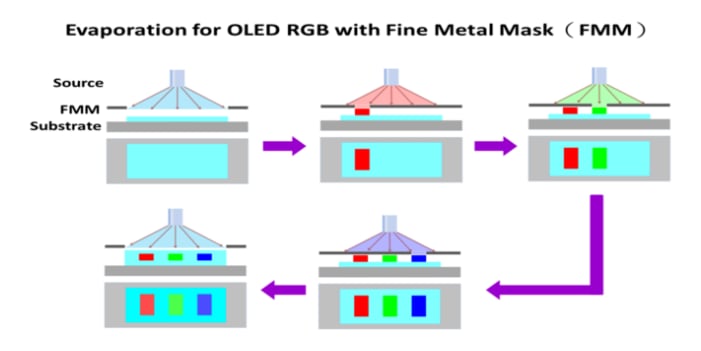

The most common method for forming organic layers is "evaporation". Evaporation here is to use electric current heating, electron beam bombardment heating and laser heating in a vacuum to evaporate the evaporated material into atoms or molecules, and then they can move in a straight line with a large free path, collide with the surface of the substrate and condense, form a thin film.

Evaporation must first be carried out in a vacuum, that is, in a device called a vacuum chamber. Fabricated large-scale LTPS backplanes, color-patterned in a vacuum chamber. The inkjet printing technology has the ability to produce under normal pressure.

Evaporation OLEDs require large-size fine metal masks, which makes this process unsuitable for the manufacture of large-size panels. The manufacturing cost of the inkjet OLED process is lower. In the use of raw materials for OLED panels, printing OLEDs saves about 90% compared with evaporation technology.

The evaporation efficiency of the organic light-emitting material of the evaporation type OLED screen is high, but the utilization rate is low. During evaporation, the organic material gas is deposited on the glass substrate indiscriminately, so the material utilization rate is low; less, can improve the efficiency of material use and other advantages.

The production of Evaporation OLED displays requires that the substrate required for large-size display panels should be higher than the 8th generation. Inkjet printing technology can be used in various types of display processes. Compared with vacuum evaporation, the inkjet method is more Large-area equipment and it has more advantages.

What is Inkjet OLED?

The inkjet printing OLED process mainly dissolves OLED organic materials into "ink", and then directly prints the "ink" less than tens of pl (one trillionth of a liter) on the surface of the substrate to form R (red), G (green), B (blue) organic light-emitting layers.

What is Evaporation OLED?

The most common method for forming organic layers is "evaporation". Evaporation here is to use electric current heating, electron beam bombardment heating and laser heating in a vacuum to evaporate the evaporated material into atoms or molecules, and then they can move in a straight line with a large free path, collide with the surface of the substrate and condense, form a thin film.

What is the difference between inkjet OLED and Evaporation OLED?

1. Different production environment requirements

Evaporation must first be carried out in a vacuum, that is, in a device called a vacuum chamber. Fabricated large-scale LTPS backplanes, color-patterned in a vacuum chamber. The inkjet printing technology has the ability to produce under normal pressure.

2. Differences in production costs

Evaporation OLEDs require large-size fine metal masks, which makes this process unsuitable for the manufacture of large-size panels. The manufacturing cost of the inkjet OLED process is lower. In the use of raw materials for OLED panels, printing OLEDs saves about 90% compared with evaporation technology.

3. Raw material utilization efficiency

The evaporation efficiency of the organic light-emitting material of the evaporation type OLED screen is high, but the utilization rate is low. During evaporation, the organic material gas is deposited on the glass substrate indiscriminately, so the material utilization rate is low; less, can improve the efficiency of material use and other advantages.

4. Large size application

The production of Evaporation OLED displays requires that the substrate required for large-size display panels should be higher than the 8th generation. Inkjet printing technology can be used in various types of display processes. Compared with vacuum evaporation, the inkjet method is more Large-area equipment and it has more advantages.