When it comes to LED screens, I believe everyone will first think of the AMOLED panel technology that is currently mixed on mobile phones, but the problem is that if you connect "miniLED", "microLED" and AMOLED, it will be just right. Made a big mistake.

why? Because the full name of AMOLED is Active-Matrix Organic Light-Emitting Diode. Please pay attention to the word "Organic", which refers to AMOLED, or all OLED screens, where light is emitted by the organic compound coating between the positive and negative electrodes-when electrons pass through In the case of organic matter, it produces a mechanism called excitation to the organic matter, which in turn causes the organic matter to emit colored light.

However, whether it is for miniLEDs or microLEDs, their internal luminescence does not rely on organic coatings, but inorganic metal semiconductors that are more "old" in nature and simpler in principle, such as gallium phosphide and gallium nitride. , Zinc selenide, aluminum carbonitride, etc.

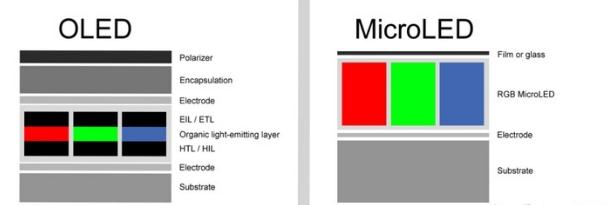

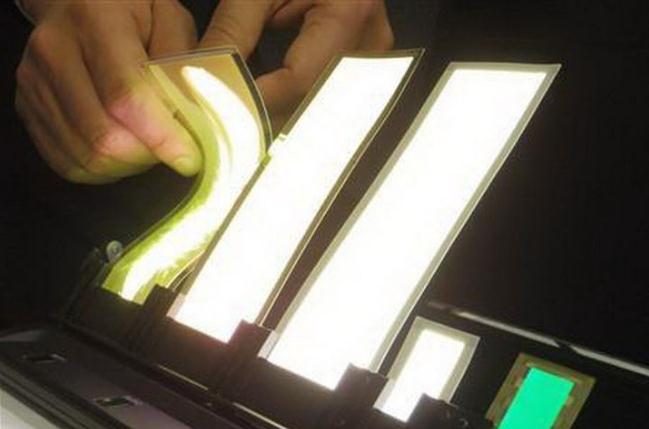

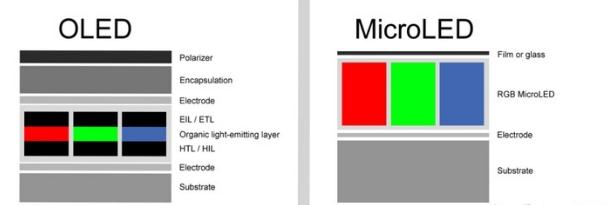

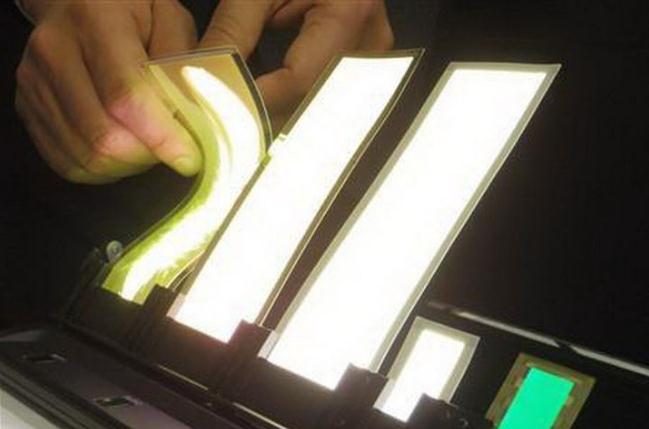

We put two pictures and everyone can understand the difference between organic light-emitting diodes and inorganic light-emitting diodes. Simply put, organic light-emitting diodes emit light from an organic thin film in an electrode sandwich, so OLED must have a thin "layer" in appearance and shape. Even the OLED shown below, which actually has only one pixel, looks like paper. of.

Thin film organic LED

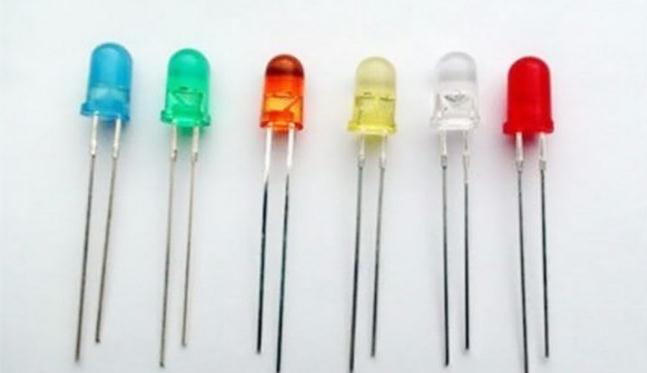

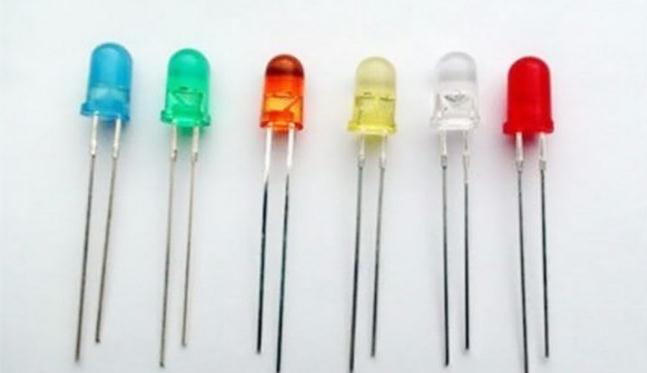

In contrast, the inorganic light-emitting diode technology based on miniLED and microLED appeared much earlier than the organic light-emitting film. As early as 1961, Texas Instruments discovered the principle of excited light for metal semiconductors. Then in 1962, General Electric developed the world's first practical inorganic light-emitting diode product. And it is this finished product that determines that most of the inorganic light-emitting diodes of later generations look like this:

This is the most typical inorganic LED

If the organic light-emitting diode is a layer of light-emitting composite film body, then the inorganic light-emitting diode is a small light bulb. This not only stems from their different circuit structures, but also determines their differences in product form and even usage.

The difference between miniLED and microLED, backlight and screen

After understanding the nature of inorganic light-emitting diodes, or miniLED and microLED "bulbs", we can finally understand their crucial differences in technology, form, and use.

Apple’s Pro Display XDR is currently one of the cheapest mini LED backlit displays, you read it right, it’s cheap

Simply put, miniLED is "small LED lamp beads"-this is small, compared with ordinary LED bulbs. But please note that every light-emitting unit (or every "bulb") is still not small enough to be used as a screen pixel, so when we talk about "miniLED screen", this is actually a wrong statement. Because miniLED itself cannot be used as a screen panel, its real use is actually a backlight module for LCD screens.

Compared with the traditional side backlight or the old-fashioned direct backlight, the advantages and disadvantages of miniLED are very simple and crude. The first advantage is that because each backlight "bulb" is smaller, it can achieve a more precise dynamic backlight effect. While effectively improving the brightness and contrast of the screen, it can also suppress the traditional large light bulb dynamic backlight caused between the bright and dark areas of the screen. Glare phenomenon. The disadvantages are mainly the high energy consumption, high heat generation, high cost caused by the high-density LED backlight module, and the problem of the overall thickness of the screen caused by the liquid crystal display. It is necessary to know that there are currently no miniLED displays in the industry that are less than 20,000 yuan. MSI’s Creator 17 is expected to become the largest in history because of its small screen size and correspondingly "shrinking" in the scale of miniLED modules. Cheap miniLED backlit screen devices, nothing more.

But when it comes to high cost, miniLEDs are still not good enough for microLEDs. Because the essence of microLED is to make the "light beads" on the miniLED smaller and denser, and then use the entire "LED light board" as a self-luminous display panel. In a sense, the essential principle of microLED is exactly the same as that of LED billboards on the street, except that the density of the lamp beads on it is several million to tens of millions of times higher.

Sony Crystal LED system, the only microLED screen currently on sale, with a top price of US$5.8 million, exclusive to local tyrants

Compared with organic light-emitting diodes (OLED), microLEDs based on the principle of inorganic light-emitting diodes are self-luminous screen panels like the former, and they also have a series of advantages such as high brightness, ultra-low latency, and large viewing angles. And because inorganic light-emitting diodes are based on metal semiconductors (rather than organics) with more stable properties and lower resistance, they have the advantages of lower power consumption, higher temperature and lower temperature resistance, and longer service life compared to OLEDs. In this case, the cost is so high that almost no one can afford it, and it may just be the only disadvantage of microLED.

why? Because the full name of AMOLED is Active-Matrix Organic Light-Emitting Diode. Please pay attention to the word "Organic", which refers to AMOLED, or all OLED screens, where light is emitted by the organic compound coating between the positive and negative electrodes-when electrons pass through In the case of organic matter, it produces a mechanism called excitation to the organic matter, which in turn causes the organic matter to emit colored light.

However, whether it is for miniLEDs or microLEDs, their internal luminescence does not rely on organic coatings, but inorganic metal semiconductors that are more "old" in nature and simpler in principle, such as gallium phosphide and gallium nitride. , Zinc selenide, aluminum carbonitride, etc.

We put two pictures and everyone can understand the difference between organic light-emitting diodes and inorganic light-emitting diodes. Simply put, organic light-emitting diodes emit light from an organic thin film in an electrode sandwich, so OLED must have a thin "layer" in appearance and shape. Even the OLED shown below, which actually has only one pixel, looks like paper. of.

Thin film organic LED

In contrast, the inorganic light-emitting diode technology based on miniLED and microLED appeared much earlier than the organic light-emitting film. As early as 1961, Texas Instruments discovered the principle of excited light for metal semiconductors. Then in 1962, General Electric developed the world's first practical inorganic light-emitting diode product. And it is this finished product that determines that most of the inorganic light-emitting diodes of later generations look like this:

This is the most typical inorganic LED

If the organic light-emitting diode is a layer of light-emitting composite film body, then the inorganic light-emitting diode is a small light bulb. This not only stems from their different circuit structures, but also determines their differences in product form and even usage.

The difference between miniLED and microLED, backlight and screen

After understanding the nature of inorganic light-emitting diodes, or miniLED and microLED "bulbs", we can finally understand their crucial differences in technology, form, and use.

Apple’s Pro Display XDR is currently one of the cheapest mini LED backlit displays, you read it right, it’s cheap

Simply put, miniLED is "small LED lamp beads"-this is small, compared with ordinary LED bulbs. But please note that every light-emitting unit (or every "bulb") is still not small enough to be used as a screen pixel, so when we talk about "miniLED screen", this is actually a wrong statement. Because miniLED itself cannot be used as a screen panel, its real use is actually a backlight module for LCD screens.

Compared with the traditional side backlight or the old-fashioned direct backlight, the advantages and disadvantages of miniLED are very simple and crude. The first advantage is that because each backlight "bulb" is smaller, it can achieve a more precise dynamic backlight effect. While effectively improving the brightness and contrast of the screen, it can also suppress the traditional large light bulb dynamic backlight caused between the bright and dark areas of the screen. Glare phenomenon. The disadvantages are mainly the high energy consumption, high heat generation, high cost caused by the high-density LED backlight module, and the problem of the overall thickness of the screen caused by the liquid crystal display. It is necessary to know that there are currently no miniLED displays in the industry that are less than 20,000 yuan. MSI’s Creator 17 is expected to become the largest in history because of its small screen size and correspondingly "shrinking" in the scale of miniLED modules. Cheap miniLED backlit screen devices, nothing more.

But when it comes to high cost, miniLEDs are still not good enough for microLEDs. Because the essence of microLED is to make the "light beads" on the miniLED smaller and denser, and then use the entire "LED light board" as a self-luminous display panel. In a sense, the essential principle of microLED is exactly the same as that of LED billboards on the street, except that the density of the lamp beads on it is several million to tens of millions of times higher.

Sony Crystal LED system, the only microLED screen currently on sale, with a top price of US$5.8 million, exclusive to local tyrants

Compared with organic light-emitting diodes (OLED), microLEDs based on the principle of inorganic light-emitting diodes are self-luminous screen panels like the former, and they also have a series of advantages such as high brightness, ultra-low latency, and large viewing angles. And because inorganic light-emitting diodes are based on metal semiconductors (rather than organics) with more stable properties and lower resistance, they have the advantages of lower power consumption, higher temperature and lower temperature resistance, and longer service life compared to OLEDs. In this case, the cost is so high that almost no one can afford it, and it may just be the only disadvantage of microLED.